Serpentine spring coupling with serpentine spring plate as the elastic element, can withstand large torque, widely used in heavy machinery and general machinery occasions.

■ Main technical performance

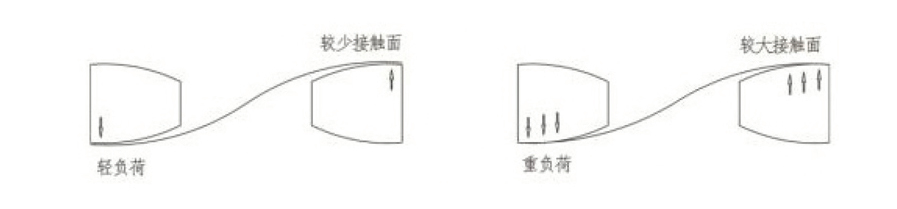

The two tooth surfaces of the snake spring coupling are composed of a plurality of curved surfaces, and the contact area of the tooth surface can be determined according to the change of the load, so that the load impact and the change of the load can be greater, so that the starting or the load is safer when the load is uneven. And it can absorb a lot of vibration through the flexible transmission of the spring

The force has a torsion buffer of up to 30%, which can effectively protect the drive device and the driven device. It is suitable for medium and high-power transmission shafting with two coaxial axes, and has certain compensation for the relative deviation of two axes and vibration reduction and buffer functions. The working temperature is -30℃~+150℃, and the transmission torque range is 45~800000N.m.

● Mainly used in belt conveyor, fan, crusher, reducer, metallurgical machinery, mining machinery, lifting machinery, etc.

● Large range of variable load, safe starting, high transmission efficiency, reliable operation.

● Simple structure, convenient installation and disassembly, allowing a large installation deviation.

● The selection of expanded sleeve type is easy to disassemble, and can be directly cold assembled and disassembled, reducing the manpower and material resources of disassembly.